Buy Feathered Dinosaurs Beipiaosaurus Realistic Dinosaur Statue AD-144

What is an Animatronic Dinosaur?

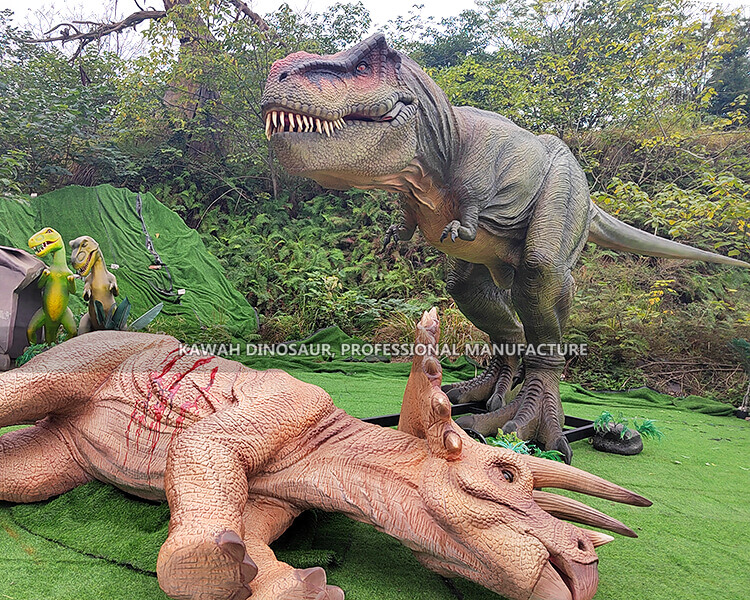

An animatronic dinosaur is a lifelike model made with steel frames, motors, and high-density sponge, inspired by dinosaur fossils. These models can move their heads, blink, open and close their mouths, and even produce sounds, water mist, or fire effects.

Animatronic dinosaurs are popular in museums, theme parks, and exhibitions, drawing crowds with their realistic appearance and movements. They provide both entertainment and educational value, recreating the ancient world of dinosaurs and helping visitors, especially children, better understand these fascinating creatures.

Dinosaur Manufacturing Process

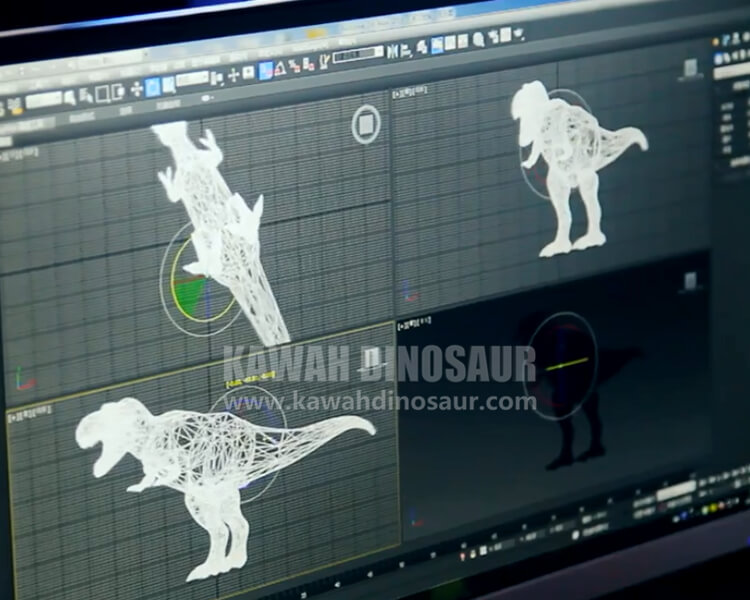

1. Drawing Design

* According to the species of the dinosaur, the proportion of limbs, and the number of movements, and combined with the needs of the customer, the production drawings of the dinosaur model are designed and produced.

2. Mechanical Framing

* Make the dinosaur steel frame according to the drawings and install the motors. Over 24 hours of steel frame aging inspection, including motions debugging, welding points firmness inspection and motors circuit inspection.

3. Body Modeling

* Use high-density sponges of different materials to create the outline of the dinosaur. Hard foam sponge is used for detail engraving, soft foam sponge is used for motion point, and fireproof sponge is used for indoor use.

4. Carving Texture

* Based on references and the characteristics of modern animals, the texture details of the skin are hand-carved, including facial expressions, muscle morphology and blood vessel tension, to truly restore the dinosaur's form.

5. Painting & Coloring

* Use three layers of neutral silicone gel to protect the bottom layer of the skin, including core silk and sponge, to enhance the skin's flexibility and anti-aging ability. Use national standard pigments for coloring, regular colors, bright colors, and camouflage colors are available.

6. Factory Testing

* The finished products undergo an aging test for more than 48 hours, and the aging speed is accelerated by 30%. Overload operation increases the failure rate, achieving the purpose of inspection and debugging, and ensuring product quality.

Animatronic Dinosaur Parameters

| Size: 1m to 30m in length; custom sizes available. | Net Weight: Varies by size (e.g., a 10m T-Rex weighs approximately 550kg). |

| Color: Customizable to any preference. | Accessories: Control box, speaker, fiberglass rock, infrared sensor, etc. |

| Production Time:15-30 days after payment, depending on quantity. | Power: 110/220V, 50/60Hz, or custom configurations at no extra charge. |

| Minimum Order: 1 Set. | After-Sales Service: 24-month warranty after installation. |

| Control Modes: Infrared sensor, remote control, token operation, button, touch sensing, automatic, and custom options. | |

| Usage: Suitable for dino parks, exhibitions, amusement parks, museums, theme parks, playgrounds, city plazas, shopping malls, and indoor/outdoor venues. | |

| Main Materials: High-density foam, national-standard steel frame, silicon rubber, and motors. | |

| Shipping: Options include land, air, sea, or multimodal transport. | |

| Movements: Eye blinking, Mouth opening/closing, Head movement, Arm movement, Stomach breathing, Tail swaying, Tongue movement, Sound effects, Water spray, Smoke spray. | |

| Note: Handmade products may have slight differences from pictures. | |

Dinosaur Mechanical Structure Overview

The mechanical structure of the animatronic dinosaur is critical to smooth movement and durability. Kawah Dinosaur Factory has more than 14 years of experience in manufacturing simulation models and strictly follows the quality management system. We pay special attention to key aspects such as the welding quality of the mechanical steel frame, wire arrangement, and motor aging. At the same time, we have multiple patents in steel frame design and motor adaptation.

Common animatronic dinosaur movements include:

Turning the head up and down and left and right, opening and closing the mouth, blinking eyes(LCD/mechanical), moving front paws, breathing, swinging the tail, standing, and following people.

Company Profile

Zigong KaWah Handicrafts Manufacturing Co., Ltd. is a leading professional manufacturer in the design and production of simulation model exhibits. Our goal is to help global customers build Jurassic Parks, Dinosaur Parks, Forest Parks, and various commercial exhibition activities. KaWah was established in August 2011 and is located in Zigong City, Sichuan Province. It has more than 60 employees and the factory covers 13,000 sq.m. The main products include animatronic dinosaurs, interactive amusement equipment, dinosaur costumes, fiberglass sculptures, and other customized products. With more than 14 years of experience in the simulation model industry, the company insists on continuous innovation and improvement in technical aspects such as mechanical transmission, electronic control, and artistic appearance design, and is committed to providing customers with more competitive products. So far, KaWah's products have been exported to more than 60 countries around the world and have won numerous praises.

We firmly believe that our customer's success is our success, and we warmly welcome partners from all walks of life to join us for mutual benefit and win-win cooperation!