Buy Life Size Walking Dinosaur Animatronic T-Rex AD-616

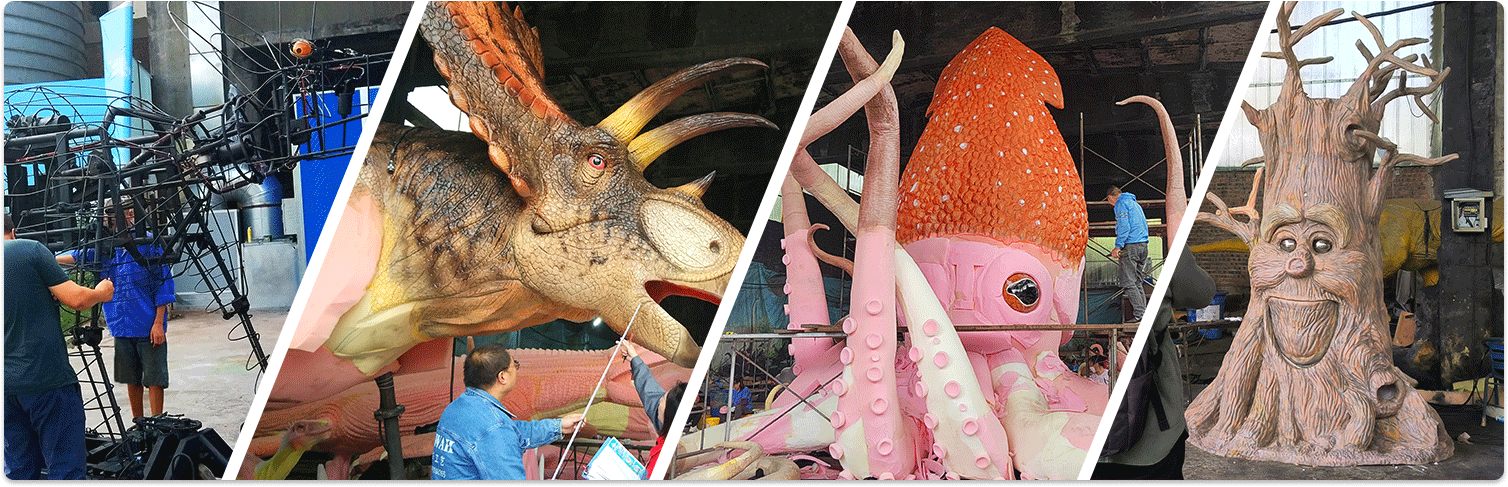

Kawah Dinosaur Team

Kawah Dinosaur is a professional simulation model manufacturer with more than 60 employees, including modeling workers, mechanical engineers, electrical engineers, designers, quality inspectors, merchandisers, operations teams, sales teams, and after-sales and installation teams. The company's annual output exceeds 300 customized models, and its products have passed ISO9001 and CE certification and can meet the needs of various use environments. In addition to providing high-quality products, we are also committed to providing a full range of services, including design, customization, project consulting, purchase, logistics, installation, and after-sales service. We are a passionate young team. We actively explore market needs and continuously optimize product design and production processes based on customer feedback, to jointly promote the development of theme parks and cultural tourism industries.

Why choose Kawah Dinosaur?

1. With 14 years of profound experience in manufacturing simulation models, Kawah Dinosaur Factory continuously optimizes production processes and techniques and has accumulated rich design and customization capabilities.

2. Our design and manufacturing team uses the customer's vision as a blueprint to ensure that each customized product fully meets the requirements in terms of visual effects and mechanical structure, and strives to restore every detail.

3. Kawah also supports customization based on customer pictures, which can flexibly meet the personalized needs of different scenarios and uses, bringing customers a customized high-standard experience.

1. Kawah Dinosaur has a self-built factory and directly serves customers with a factory direct sales model, eliminating middlemen, reducing customers' procurement costs from the source, and ensuring transparent and affordable quotations.

2. While achieving high-quality standards, we also improve cost performance by optimizing production efficiency and cost control, helping customers maximize project value within budget.

1. Kawah always puts product quality first and implements strict quality control during the production process. From the firmness of welding points, the stability of motor operation to the fineness of product appearance details, they all meet high standards.

2. Each product must pass a comprehensive aging test before leaving the factory to verify its durability and reliability in different environments. This series of rigorous tests ensures that our products are durable and stable during use and can meet various outdoor and high-frequency application scenarios.

1. Kawah provides customers with one-stop after-sales support, from the supply of free spare parts for products to on-site installation support, online video technical assistance and lifetime parts cost-price maintenance, ensuring customers worry-free use.

2. We have established a responsive service mechanism to provide flexible and efficient after-sales solutions based on the specific needs of each customer, and are committed to bringing lasting product value and secure service experience to customers.

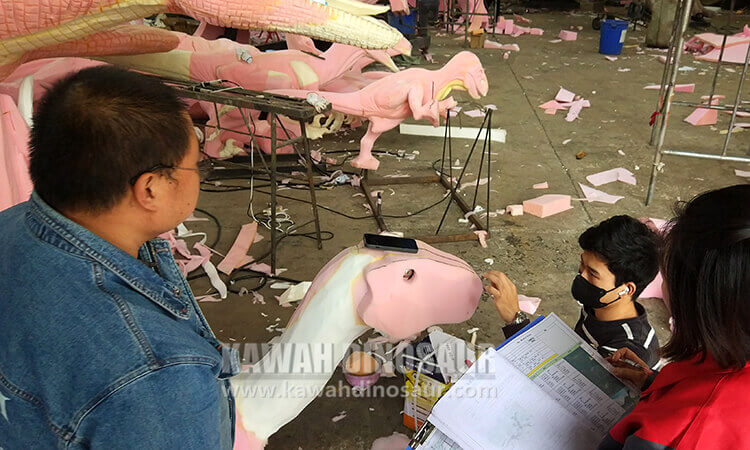

Product Quality Inspection

We attach great importance to the quality and reliability of our products, and we have always adhered to strict quality inspection standards and processes throughout the production process.

Check Welding Point

* Check whether each welding point of the steel frame structure is firm to ensure the stability and safety of the product.

Check Movement Range

* Check whether the movement range of the model reaches the specified range to improve the functionality and user experience of the product.

Check Motor Running

* Check whether the motor, reducer, and other transmission structures are running smoothly to ensure the performance and service life of the product.

Check Modeling Detail

* Check whether the details of the shape meet the standards, including appearance similarity, glue level flatness, color saturation, etc.

Check Product Size

* Check whether the product size meets the requirements, which is also one of the key indicators of quality inspection.

Check Aging Test

* The aging test of a product before leaving the factory is an important step in ensuring product reliability and stability.

Installation

Installation of 20 m Brachiosaurus in Santiago Forest Park, Chile

Dinosaur skeleton tunnel product has arrived at customer theme park site