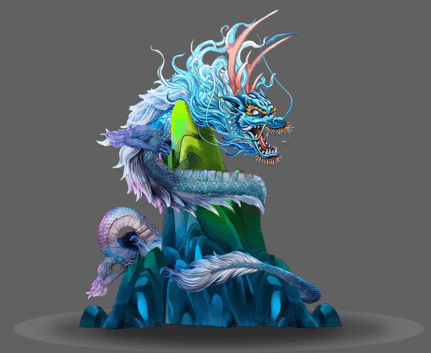

Colorful Lanterns Customized Brachiosaurus Model with Sounds Holiday Decoration CL-2602

Product Video

What is Zigong Lantern?

Zigong lanterns are traditional lantern crafts from Zigong, Sichuan, China, and part of China's intangible cultural heritage. Known for their unique craftsmanship and vibrant colors, these lanterns are made from bamboo, paper, silk, and cloth. They feature lifelike designs of characters, animals, flowers, and more, showcasing rich folk culture. The production involves material selection, design, cutting, pasting, painting, and assembly. Painting is crucial as it defines the lantern’s color and artistic value. Zigong lanterns can be customized in shape, size, and color, making them ideal for theme parks, festivals, commercial events, and more. Contact us to customize your lanterns.

Materials for Zigong Lanterns

1 Chassis Material: The chassis supports the entire lantern. Small lanterns use rectangular tubes, medium ones use 30-angle steel, and large lanterns may use U-shaped channel steel.

2 Frame Material: The frame shapes the lantern. Typically, No. 8 iron wire is used, or 6mm steel bars. For larger frames, 30-angle steel or round steel is added for reinforcement.

3 Light Source: Light sources vary by design, including LED bulbs, strips, strings, and spotlights, each creating different effects.

4 Surface Material: Surface materials depend on the design, including traditional paper, satin cloth, or recycled items like plastic bottles. Satin materials provide good light transmission and a silk-like gloss.

Zigong Lanterns Parameters

| Materials: | Steel, Silk Cloth, Bulbs, LED Strips. |

| Power: | 110/220V AC 50/60Hz (or customized). |

| Type/Size/Color: | Customizable. |

| After-sale Services: | 6 months after installation. |

| Sounds: | Matching or custom sounds. |

| Temperature Range: | -20°C to 40°C. |

| Usage: | Theme parks, festivals, commercial events, city squares, landscape decorations, etc. |

Create Your Custom Animatronic Model

Kawah Dinosaur, with over 10 years of experience, is a leading manufacturer of realistic animatronic models with strong customization capabilities. We create custom designs, including dinosaurs, land and marine animals, cartoon characters, movie characters, and more. Whether you have a design idea or a photo or video reference, we can produce high-quality animatronic models tailored to your needs. Our models are made from premium materials like steel, brushless motors, reducers, control systems, high-density sponges, and silicone, all meeting international standards.

We emphasize clear communication and customer approval throughout production to ensure satisfaction. With a skilled team and a proven history of diverse custom projects, Kawah Dinosaur is your reliable partner for creating unique animatronic models. Contact us to start customizing today!