Customized Brachiosaurus Ride Animatronic Dinosaur Ride Realistic Dino ADR-727

Product Video

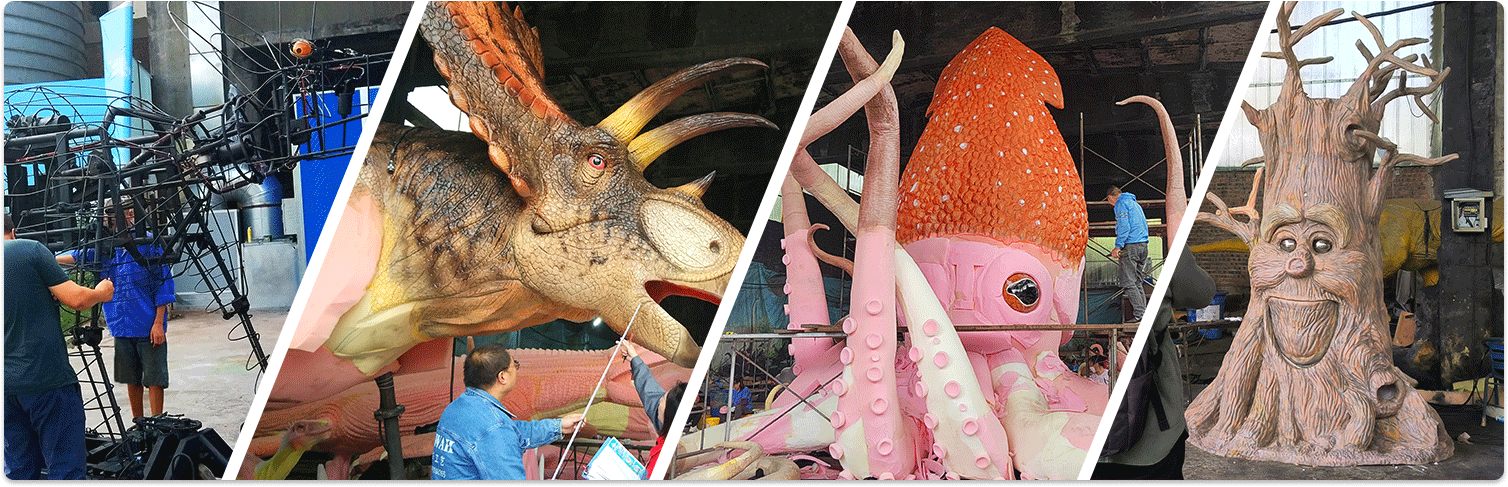

Why choose Kawah Dinosaur?

1. With 14 years of profound experience in manufacturing simulation models, Kawah Dinosaur Factory continuously optimizes production processes and techniques and has accumulated rich design and customization capabilities.

2. Our design and manufacturing team uses the customer's vision as a blueprint to ensure that each customized product fully meets the requirements in terms of visual effects and mechanical structure, and strives to restore every detail.

3. Kawah also supports customization based on customer pictures, which can flexibly meet the personalized needs of different scenarios and uses, bringing customers a customized high-standard experience.

1. Kawah Dinosaur has a self-built factory and directly serves customers with a factory direct sales model, eliminating middlemen, reducing customers' procurement costs from the source, and ensuring transparent and affordable quotations.

2. While achieving high-quality standards, we also improve cost performance by optimizing production efficiency and cost control, helping customers maximize project value within budget.

1. Kawah always puts product quality first and implements strict quality control during the production process. From the firmness of welding points, the stability of motor operation to the fineness of product appearance details, they all meet high standards.

2. Each product must pass a comprehensive aging test before leaving the factory to verify its durability and reliability in different environments. This series of rigorous tests ensures that our products are durable and stable during use and can meet various outdoor and high-frequency application scenarios.

1. Kawah provides customers with one-stop after-sales support, from the supply of free spare parts for products to on-site installation support, online video technical assistance and lifetime parts cost-price maintenance, ensuring customers worry-free use.

2. We have established a responsive service mechanism to provide flexible and efficient after-sales solutions based on the specific needs of each customer, and are committed to bringing lasting product value and secure service experience to customers.

Animatronic Dinosaur Rides Parameters

| Size: 2m to 8m in length; custom sizes available. | Net Weight: Varies by size (e.g., a 3m T-Rex weighs approximately 170kg). |

| Color: Customizable to any preference. | Accessories: Control box, speaker, fiberglass rock, infrared sensor, etc. |

| Production Time:15-30 days after payment, depending on quantity. | Power: 110/220V, 50/60Hz, or custom configurations at no extra charge. |

| Minimum Order: 1 Set. | After-Sales Service: 24-month warranty after installation. |

| Control Modes: Infrared sensor, remote control, token operation, button, touch sensing, automatic, and custom options. | |

| Usage: Suitable for dino parks, exhibitions, amusement parks, museums, theme parks, playgrounds, city plazas, shopping malls, and indoor/outdoor venues. | |

| Main Materials: High-density foam, national-standard steel frame, silicon rubber, and motors. | |

| Shipping: Options include land, air, sea, or multimodal transport. | |

| Movements: Eye blinking, Mouth opening/closing, Head movement, Arm movement, Stomach breathing, Tail swaying, Tongue movement, Sound effects, Water spray, Smoke spray. | |

| Note: Handmade products may have slight differences from pictures. | |

Dinosaur Ride Main Materials

The main materials for riding dinosaur products include stainless steel, motors, flange DC components, gear reducers, silicone rubber, high-density foam, pigments, and more.

Dinosaur Ride Main Accessories

The accessories for riding dinosaur products include ladders, coin selectors, speakers, cables, controller boxes, simulated rocks, and other essential components.