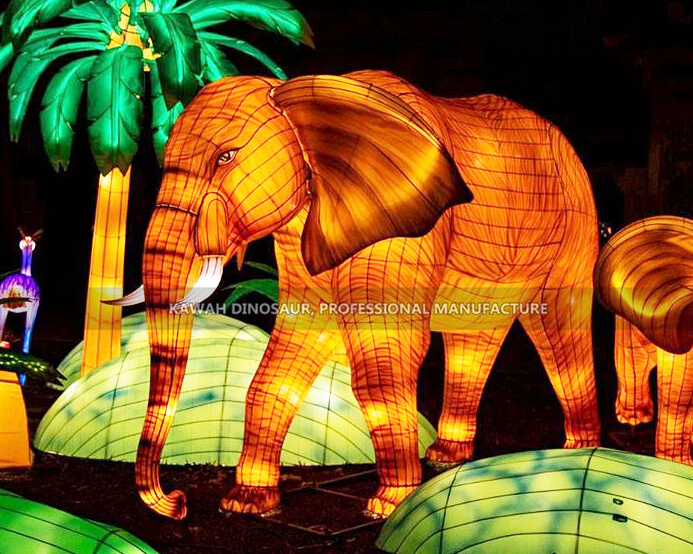

Customized Life Size Elephant Lanterns Realistic Animals Lantern China Factory CL-2645

Product Video

What is Zigong Lantern?

Zigong lanterns are traditional lantern crafts from Zigong, Sichuan, China, and part of China's intangible cultural heritage. Known for their unique craftsmanship and vibrant colors, these lanterns are made from bamboo, paper, silk, and cloth. They feature lifelike designs of characters, animals, flowers, and more, showcasing rich folk culture. The production involves material selection, design, cutting, pasting, painting, and assembly. Painting is crucial as it defines the lantern’s color and artistic value. Zigong lanterns can be customized in shape, size, and color, making them ideal for theme parks, festivals, commercial events, and more. Contact us to customize your lanterns.

Zigong lanterns production process

1 Design: Create four key drawings—renderings, construction, electrical, and mechanical diagrams—and a booklet explaining the theme, lighting, and mechanics.

2 Pattern Layout: Distribute and scale up design samples for crafting.

3 Shaping: Use wire to model parts, then weld them into 3D lantern structures. Install mechanical parts for dynamic lanterns if needed.

4 Electrical Installation: Set up LED lights, control panels, and connect motors as per design.

5 Coloring: Apply colored silk cloth to lantern surfaces based on the artist’s color instructions.

6 Art Finishing: Use painting or spraying to finalize the look in line with the design.

7 Assembly: Assemble all parts on-site to create a final lantern display matching the renderings.

Zigong Lanterns Parameters

| Materials: | Steel, Silk Cloth, Bulbs, LED Strips. |

| Power: | 110/220V AC 50/60Hz (or customized). |

| Type/Size/Color: | Customizable. |

| After-sale Services: | 6 months after installation. |

| Sounds: | Matching or custom sounds. |

| Temperature Range: | -20°C to 40°C. |

| Usage: | Theme parks, festivals, commercial events, city squares, landscape decorations, etc. |

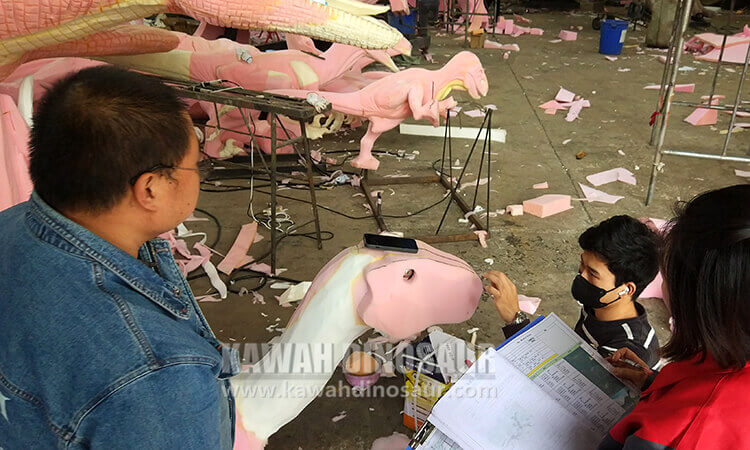

Product Quality Inspection

We attach great importance to the quality and reliability of products, and we have always adhered to strict quality inspection standards and processes throughout the production process.

Check Welding Point

* Check whether each welding point of the steel frame structure is firm to ensure the stability and safety of the product.

Check Movement Range

* Check whether the movement range of the model reaches the specified range to improve the functionality and user experience of the product.

Check Motor Running

* Check whether the motor, reducer, and other transmission structures are running smoothly to ensure the performance and service life of the product.

Check Modeling Detail

* Check whether the details of the shape meet the standards, including appearance similarity, glue level flatness, color saturation, etc.

Check Product Size

* Check whether the product size meets the requirements, which is also one of the key indicators of quality inspection.

Check Aging Test

* The aging test of a product before leaving the factory is an important step in ensuring product reliability and stability.