Dinosaur Handmade Giant Amargasaurus Fossil Dinosaur Skull Replicas for School Education SR-1816

What Are Dinosaur Skeleton Replicas?

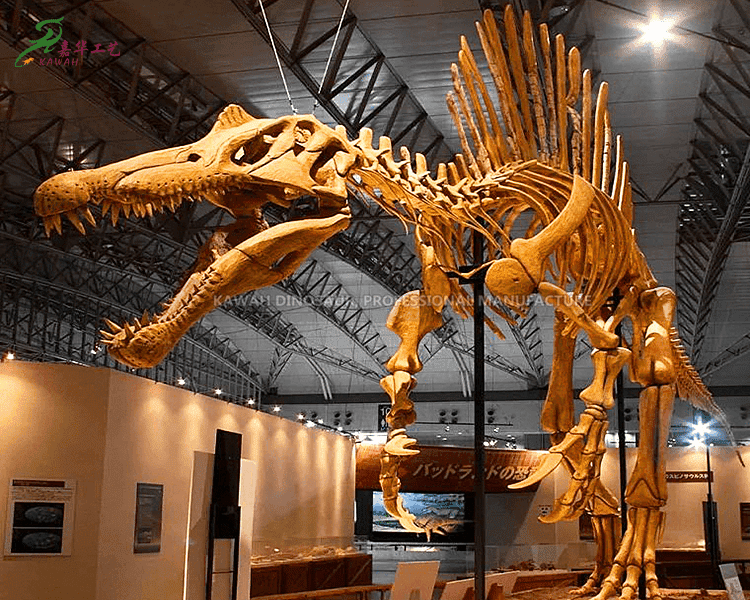

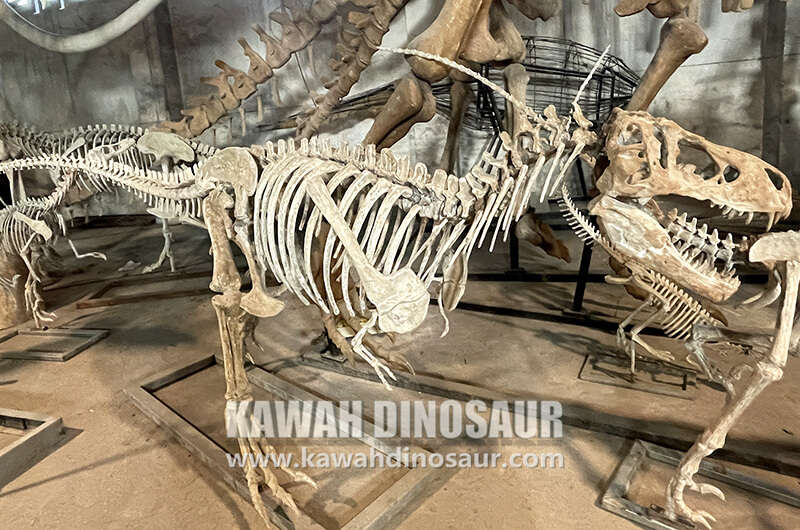

Dinosaur skeleton fossil replicas are fiberglass recreations of real dinosaur fossils, crafted through sculpting, weathering, and coloring techniques. These replicas vividly showcase the majesty of prehistoric creatures while serving as an educational tool to promote paleontological knowledge. Each replica is designed with precision, adhering to skeletal literature reconstructed by archaeologists. Their realistic appearance, durability, and ease of transportation and installation make them ideal for dinosaur parks, museums, science centers, and educational exhibitions.

Dinosaur Skeleton Fossil Parameters

| Main Materials: | Advanced Resin, Fiberglass. |

| Usage: | Dino parks, Dinosaur Worlds, Exhibitions, Amusement parks, Theme parks, Museums, Playgrounds, Shopping malls, Schools, Indoor/Outdoor venues. |

| Size: | 1-20 meters long (custom sizes available). |

| Movements: | None. |

| Packaging: | Wrapped in bubble film and packed in a wooden case; each skeleton is individually packaged. |

| After-Sales Service: | 12 Months. |

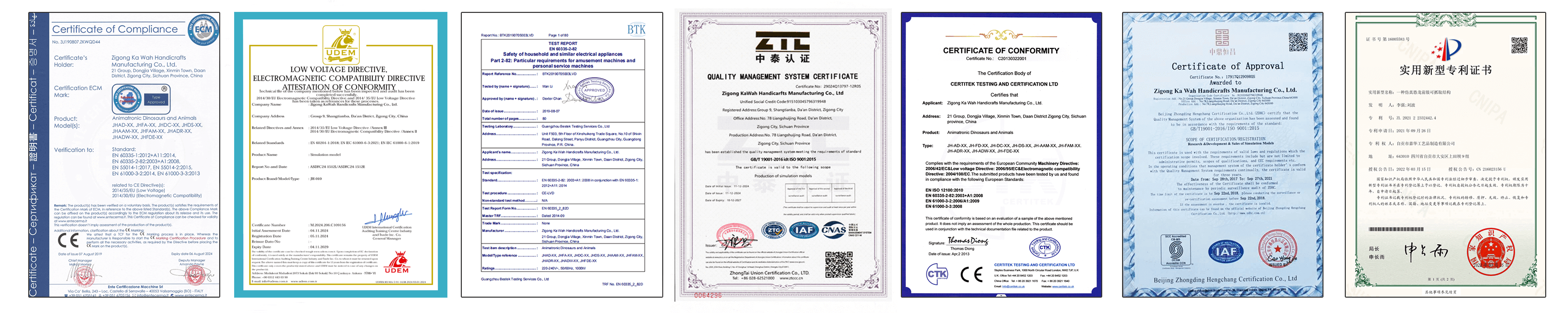

| Certifications: | CE, ISO. |

| Sound: | None. |

| Note: | Slight differences may occur due to hand-made production. |

Kawah Dinosaur Certifications

At Kawah Dinosaur, we prioritize product quality as the foundation of our enterprise. We meticulously select materials, control every production step, and conduct 19 strict testing procedures. Each product undergoes a 24-hour aging test after the frame and final assembly are completed. To ensure customer satisfaction, we provide videos and photos at three key stages: frame construction, artistic shaping, and completion. Products are shipped only after receiving customer confirmation at least three times. Our raw materials and products meet industry standards and are certified by CE and ISO. Additionally, we have obtained numerous patent certificates, showcasing our commitment to innovation and quality.

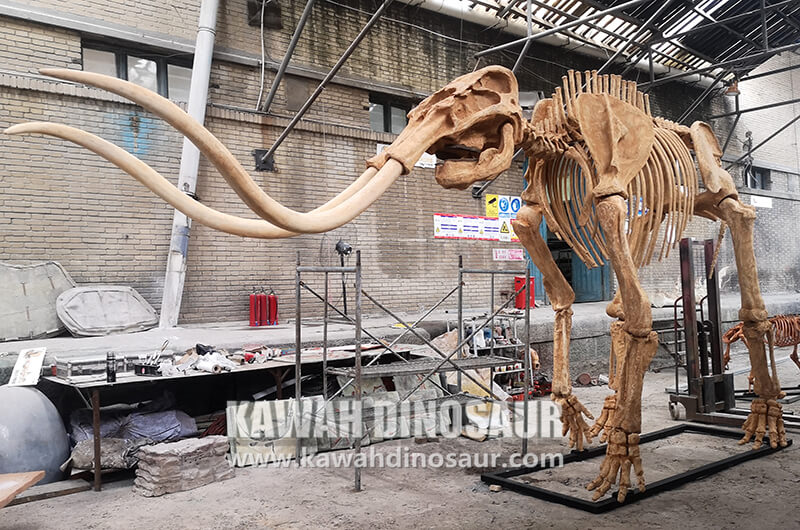

Kawah Production Status

Eight meters tall giant gorilla statue animatronic King Kong in production

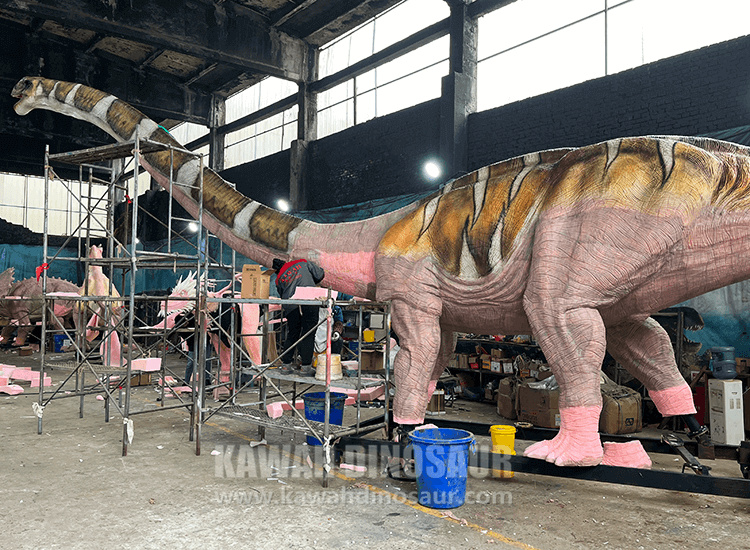

Skin processing of 20m giant Mamenchisaurus Model

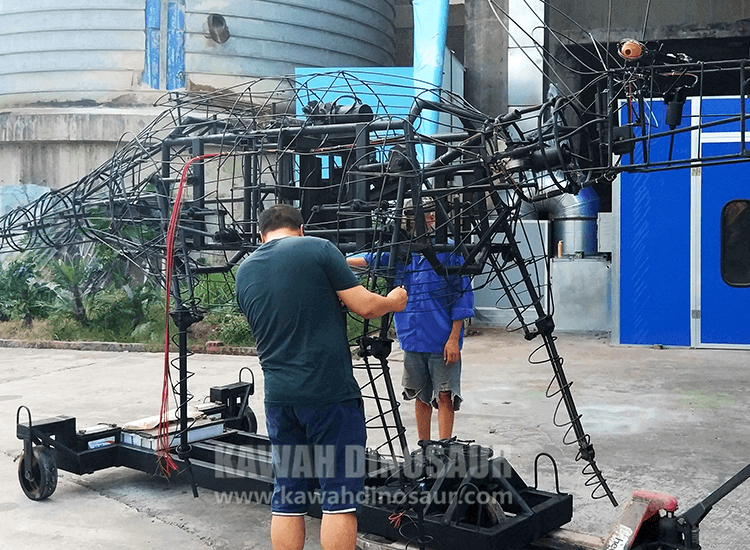

Animatronic dinosaur mechanical frame inspection

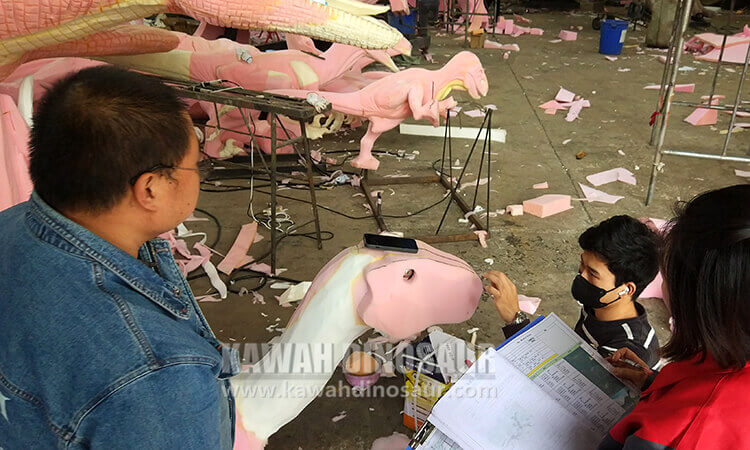

Product Quality Inspection

We attach great importance to the quality and reliability of products, and we have always adhered to strict quality inspection standards and processes throughout the production process.

Check Welding Point

* Check whether each welding point of the steel frame structure is firm to ensure the stability and safety of the product.

Check Movement Range

* Check whether the movement range of the model reaches the specified range to improve the functionality and user experience of the product.

Check Motor Running

* Check whether the motor, reducer, and other transmission structures are running smoothly to ensure the performance and service life of the product.

Check Modeling Detail

* Check whether the details of the shape meet the standards, including appearance similarity, glue level flatness, color saturation, etc.

Check Product Size

* Check whether the product size meets the requirements, which is also one of the key indicators of quality inspection.

Check Aging Test

* The aging test of a product before leaving the factory is an important step in ensuring product reliability and stability.