Entertainment Stage Walking Dinosaur Animatronic Velociraptor AD-617

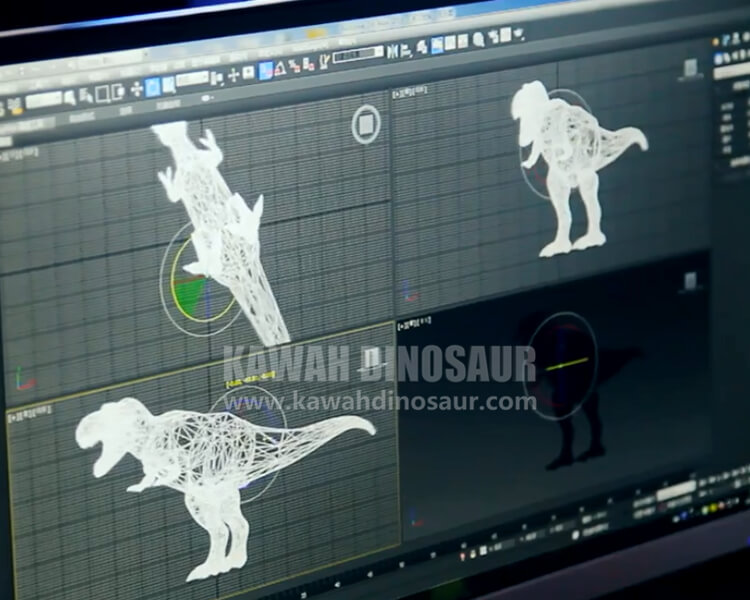

Dinosaur Manufacturing Process

1. Drawing Design

* According to the species of the dinosaur, the proportion of limbs, and the number of movements, and combined with the needs of the customer, the production drawings of the dinosaur model are designed and produced.

2. Mechanical Framing

* Make the dinosaur steel frame according to the drawings and install the motors. Over 24 hours of steel frame aging inspection, including motions debugging, welding points firmness inspection and motors circuit inspection.

3. Body Modeling

* Use high-density sponges of different materials to create the outline of the dinosaur. Hard foam sponge is used for detail engraving, soft foam sponge is used for motion point, and fireproof sponge is used for indoor use.

4. Carving Texture

* Based on references and the characteristics of modern animals, the texture details of the skin are hand-carved, including facial expressions, muscle morphology and blood vessel tension, to truly restore the dinosaur's form.

5. Painting & Coloring

* Use three layers of neutral silicone gel to protect the bottom layer of the skin, including core silk and sponge, to enhance the skin's flexibility and anti-aging ability. Use national standard pigments for coloring, regular colors, bright colors, and camouflage colors are available.

6. Factory Testing

* The finished products undergo an aging test for more than 48 hours, and the aging speed is accelerated by 30%. Overload operation increases the failure rate, achieving the purpose of inspection and debugging, and ensuring product quality.

Kawah Production Status

Making a 15-meter Spinosaurus dinosaur statue

Western dragon head statue coloring

Customized 6 meters tall giant octopus model skin processing for Vietnamese customers

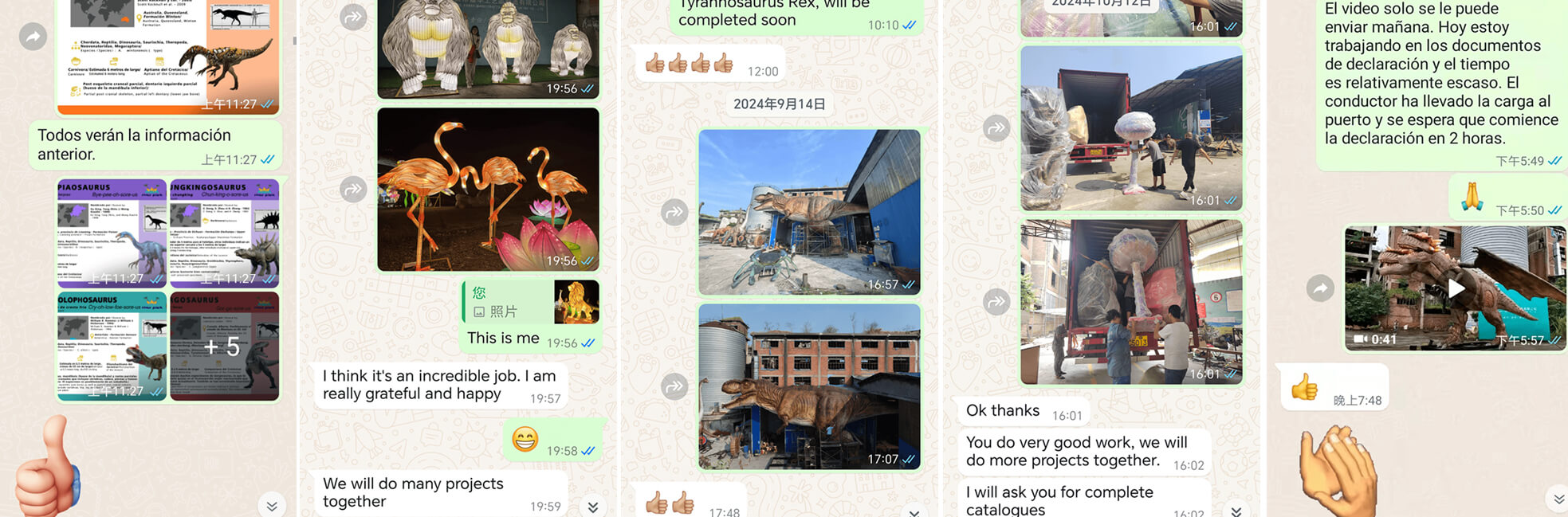

Customer Comments

Kawah Dinosaur specializes in manufacturing high-quality, highly realistic dinosaur models. Customers consistently praise both the reliable craftsmanship and the lifelike appearance of our products. Our professional service, from pre-sales consultation to after-sales support, has also earned widespread acclaim. Many customers highlight the superior realism and quality of our models compared to other brands, noting our reasonable pricing. Others commend our attentive customer service and thoughtful after-sales care, solidifying Kawah Dinosaur as a trusted partner in the industry.

Kawah Dinosaur Certifications

At Kawah Dinosaur, we prioritize product quality as the foundation of our enterprise. We meticulously select materials, control every production step, and conduct 19 strict testing procedures. Each product undergoes a 24-hour aging test after the frame and final assembly are completed. To ensure customer satisfaction, we provide videos and photos at three key stages: frame construction, artistic shaping, and completion. Products are shipped only after receiving customer confirmation at least three times. Our raw materials and products meet industry standards and are certified by CE and ISO. Additionally, we have obtained numerous patent certificates, showcasing our commitment to innovation and quality.