Kawah Dinosaur Factory Giant Triceratops Realistic Dinosaur Animatronic Dinosaurs For Sale AD-099

What is an Animatronic Dinosaur?

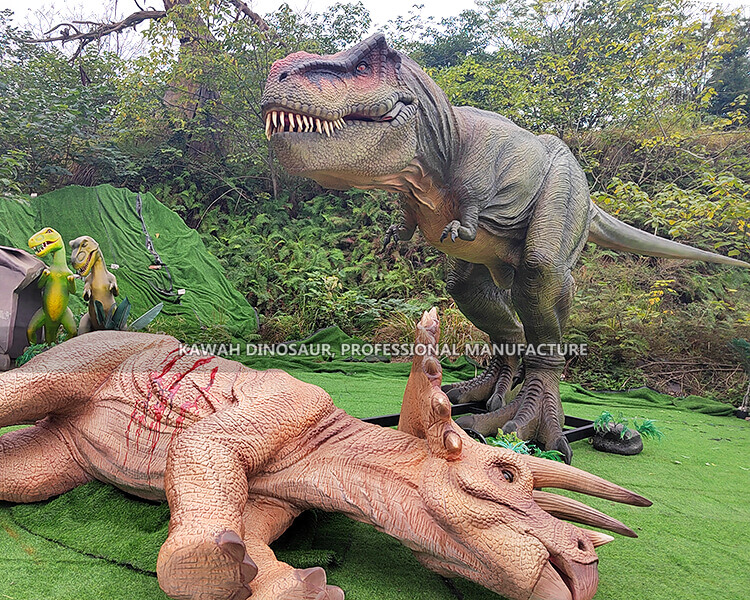

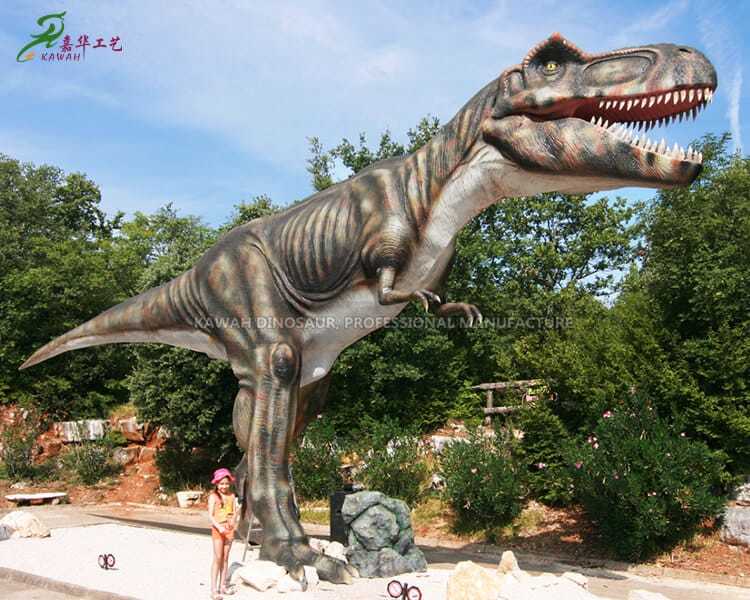

An animatronic dinosaur is a lifelike model made with steel frames, motors, and high-density sponge, inspired by dinosaur fossils. These models can move their heads, blink, open and close their mouths, and even produce sounds, water mist, or fire effects.

Animatronic dinosaurs are popular in museums, theme parks, and exhibitions, drawing crowds with their realistic appearance and movements. They provide both entertainment and educational value, recreating the ancient world of dinosaurs and helping visitors, especially children, better understand these fascinating creatures.

Dinosaur Manufacturing Process

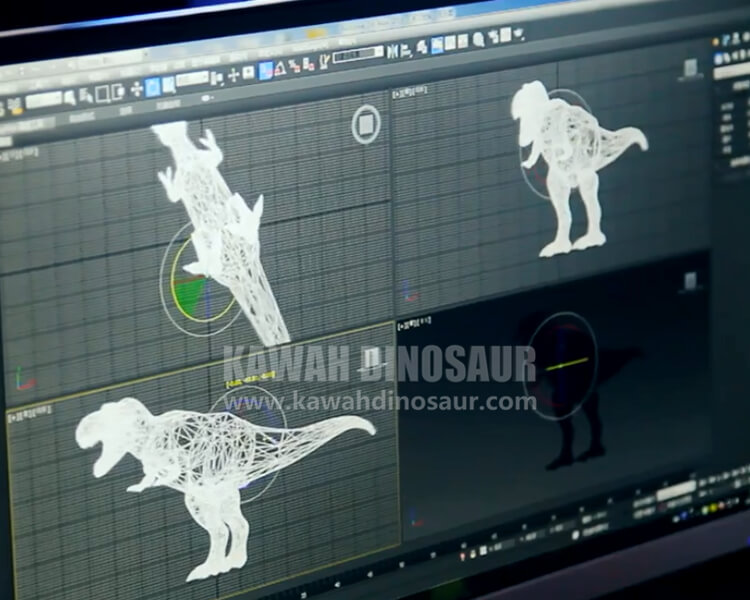

1. Drawing Design

* According to the species of the dinosaur, the proportion of limbs, and the number of movements, and combined with the needs of the customer, the production drawings of the dinosaur model are designed and produced.

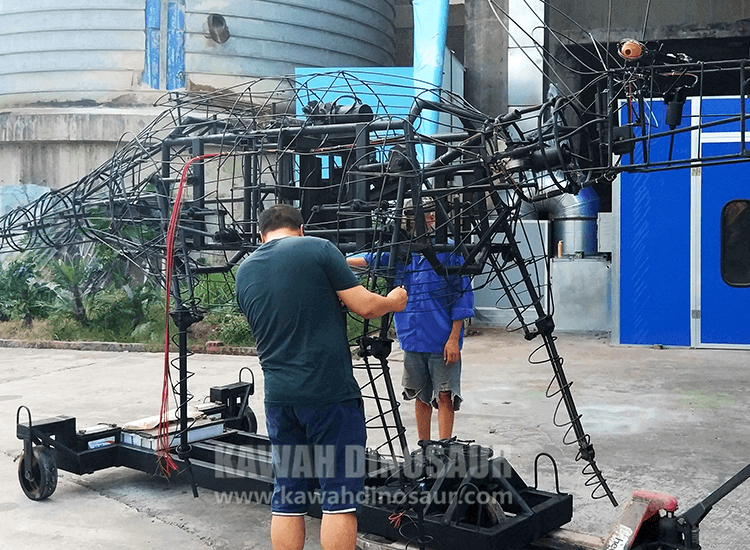

2. Mechanical Framing

* Make the dinosaur steel frame according to the drawings and install the motors. Over 24 hours of steel frame aging inspection, including motions debugging, welding points firmness inspection and motors circuit inspection.

3. Body Modeling

* Use high-density sponges of different materials to create the outline of the dinosaur. Hard foam sponge is used for detail engraving, soft foam sponge is used for motion point, and fireproof sponge is used for indoor use.

4. Carving Texture

* Based on references and the characteristics of modern animals, the texture details of the skin are hand-carved, including facial expressions, muscle morphology and blood vessel tension, to truly restore the dinosaur's form.

5. Painting & Coloring

* Use three layers of neutral silicone gel to protect the bottom layer of the skin, including core silk and sponge, to enhance the skin's flexibility and anti-aging ability. Use national standard pigments for coloring, regular colors, bright colors, and camouflage colors are available.

6. Factory Testing

* The finished products undergo an aging test for more than 48 hours, and the aging speed is accelerated by 30%. Overload operation increases the failure rate, achieving the purpose of inspection and debugging, and ensuring product quality.

Types of Simulated Dinosaurs

Kawah Dinosaur Factory offers three types of customizable simulated dinosaurs, each with unique features suited to different scenarios. Choose based on your needs and budget to find the best fit for your purpose.

· Sponge material (with movements)

It uses high-density sponge as the main material, which is soft to the touch. It is equipped with internal motors to achieve a variety of dynamic effects and enhance attraction. This type is more expensive requires regular maintenance, and is suitable for scenarios that require high interactivity.

· Sponge material (no movement)

It also uses high-density sponge as the main material, which is soft to the touch. It is supported by a steel frame inside, but it does not contain motors and cannot move. This type has the lowest cost and simple post-maintenance and is suitable for scenes with limited budget or no dynamic effects.

· Fiberglass material (no movement)

The main material is fiberglass, which is hard to the touch. It is supported by a steel frame inside and has no dynamic function. The appearance is more realistic and can be used in indoor and outdoor scenes. Post-maintenance is equally convenient and suitable for scenes with higher appearance requirements.

Animatronic Dinosaur Parameters

| Size: 1m to 30m in length; custom sizes available. | Net Weight: Varies by size (e.g., a 10m T-Rex weighs approximately 550kg). |

| Color: Customizable to any preference. | Accessories: Control box, speaker, fiberglass rock, infrared sensor, etc. |

| Production Time:15-30 days after payment, depending on quantity. | Power: 110/220V, 50/60Hz, or custom configurations at no extra charge. |

| Minimum Order: 1 Set. | After-Sales Service: 24-month warranty after installation. |

| Control Modes: Infrared sensor, remote control, token operation, button, touch sensing, automatic, and custom options. | |

| Usage: Suitable for dino parks, exhibitions, amusement parks, museums, theme parks, playgrounds, city plazas, shopping malls, and indoor/outdoor venues. | |

| Main Materials: High-density foam, national-standard steel frame, silicon rubber, and motors. | |

| Shipping: Options include land, air, sea, or multimodal transport. | |

| Movements: Eye blinking, Mouth opening/closing, Head movement, Arm movement, Stomach breathing, Tail swaying, Tongue movement, Sound effects, Water spray, Smoke spray. | |

| Note: Handmade products may have slight differences from pictures. | |

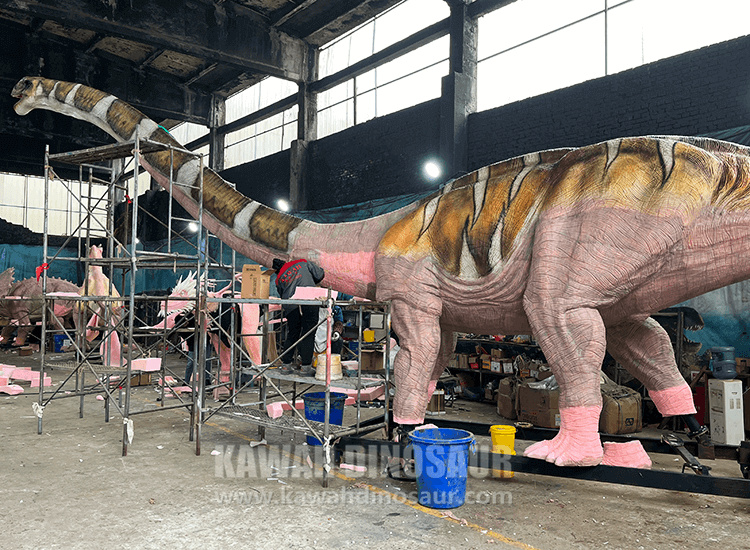

Kawah Production Status

Eight meters tall giant gorilla statue animatronic King Kong in production

Skin processing of 20m giant Mamenchisaurus Model