Lifelike Frogs Lanterns Festival Realistic Insects Waterproof Lantern With Light Manufacturer CL-2622

Product Video

What is Zigong Lantern?

Zigong lanterns are traditional lantern crafts from Zigong, Sichuan, China, and part of China's intangible cultural heritage. Known for their unique craftsmanship and vibrant colors, these lanterns are made from bamboo, paper, silk, and cloth. They feature lifelike designs of characters, animals, flowers, and more, showcasing rich folk culture. The production involves material selection, design, cutting, pasting, painting, and assembly. Painting is crucial as it defines the lantern’s color and artistic value. Zigong lanterns can be customized in shape, size, and color, making them ideal for theme parks, festivals, commercial events, and more. Contact us to customize your lanterns.

Zigong lanterns production process

1 Design: Create four key drawings—renderings, construction, electrical, and mechanical diagrams—and a booklet explaining the theme, lighting, and mechanics.

2 Pattern Layout: Distribute and scale up design samples for crafting.

3 Shaping: Use wire to model parts, then weld them into 3D lantern structures. Install mechanical parts for dynamic lanterns if needed.

4 Electrical Installation: Set up LED lights, control panels, and connect motors as per design.

5 Coloring: Apply colored silk cloth to lantern surfaces based on the artist’s color instructions.

6 Art Finishing: Use painting or spraying to finalize the look in line with the design.

7 Assembly: Assemble all parts on-site to create a final lantern display matching the renderings.

Materials for Zigong Lanterns

1 Chassis Material: The chassis supports the entire lantern. Small lanterns use rectangular tubes, medium ones use 30-angle steel, and large lanterns may use U-shaped channel steel.

2 Frame Material: The frame shapes the lantern. Typically, No. 8 iron wire is used, or 6mm steel bars. For larger frames, 30-angle steel or round steel is added for reinforcement.

3 Light Source: Light sources vary by design, including LED bulbs, strips, strings, and spotlights, each creating different effects.

4 Surface Material: Surface materials depend on the design, including traditional paper, satin cloth, or recycled items like plastic bottles. Satin materials provide good light transmission and a silk-like gloss.

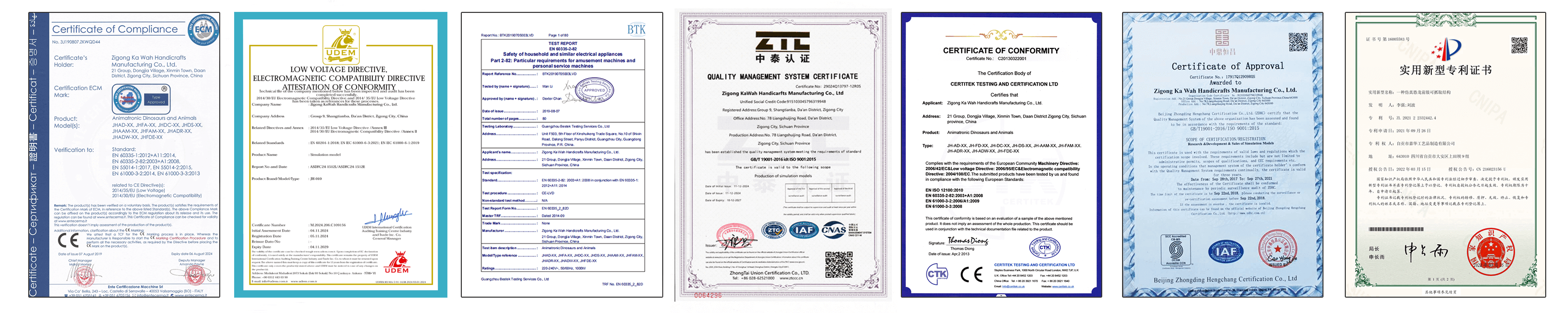

Kawah Dinosaur Certifications

At Kawah Dinosaur, we prioritize product quality as the foundation of our enterprise. We meticulously select materials, control every production step, and conduct 19 strict testing procedures. Each product undergoes a 24-hour aging test after the frame and final assembly are completed. To ensure customer satisfaction, we provide videos and photos at three key stages: frame construction, artistic shaping, and completion. Products are shipped only after receiving customer confirmation at least three times. Our raw materials and products meet industry standards and are certified by CE and ISO. Additionally, we have obtained numerous patent certificates, showcasing our commitment to innovation and quality.