Realistic Animatronic Sarcosuchus Statue Animatronic Animal Crocodile Statue AA-1203

Product Video

Animatronic Animals Features

· Realistic Skin Texture

Hand-Crafted with high-density foam and silicone rubber, our animatronic animals feature lifelike appearances and textures, offering an authentic look and feel.

· Interactive Entertainment & Learning

Designed to provide immersive experiences, our realistic animal products engage visitors with dynamic, themed entertainment and educational value.

· Reusable Design

Easily disassembled and reassembled for repeated use. Kawah factory’s installation team is available for on-site assistance.

· Durability in All Climates

Built to withstand extreme temperatures, our models feature waterproof and anti-corrosion properties for long-lasting performance.

· Customized Solutions

Tailored to your preferences, we create bespoke designs based on your requirements or drawings.

· Reliable Control System

With strict quality checks and over 30 hours of continuous testing before shipment, our systems ensure consistent and reliable performance.

Animatronic Animals Parameters

| Size: 1m to 20m in length, customizable. | Net Weight: Varies by size (e.g., a 3m tiger weighs ~80kg). |

| Color: Customizable. | Accessories: Control box, speaker, fiberglass rock, infrared sensor, etc. |

| Production Time:15-30 days, depending on quantity. | Power: 110/220V, 50/60Hz, or customizable at no extra charge. |

| Minimum Order: 1 Set. | After-Sales Service: 12 months post-installation. |

| Control Modes: Infrared sensor, remote control, coin-operated, button, touch sensing, automatic, and customizable options. | |

| Placement Options: Hanging, wall-mounted, ground display, or placed in water (waterproof and durable). | |

| Main Materials: High-density foam, national standard steel frame, silicone rubber, motors. | |

| Shipping: Options include land, air, sea, and multimodal transport. | |

| Notice: Handmade products may have slight differences from pictures. | |

| Movements: 1. Mouth opens and closes with sound. 2. Eye blinking (LCD or mechanical). 3. Neck moves up, down, left, and right. 4. Head moves up, down, left, and right. 5. Forelimb movement. 6. Chest rises and falls to simulate breathing. 7. Tail swaying. 8. Water spray. 9. Smoke spray. 10. Tongue movement. | |

Types of Simulated Animals

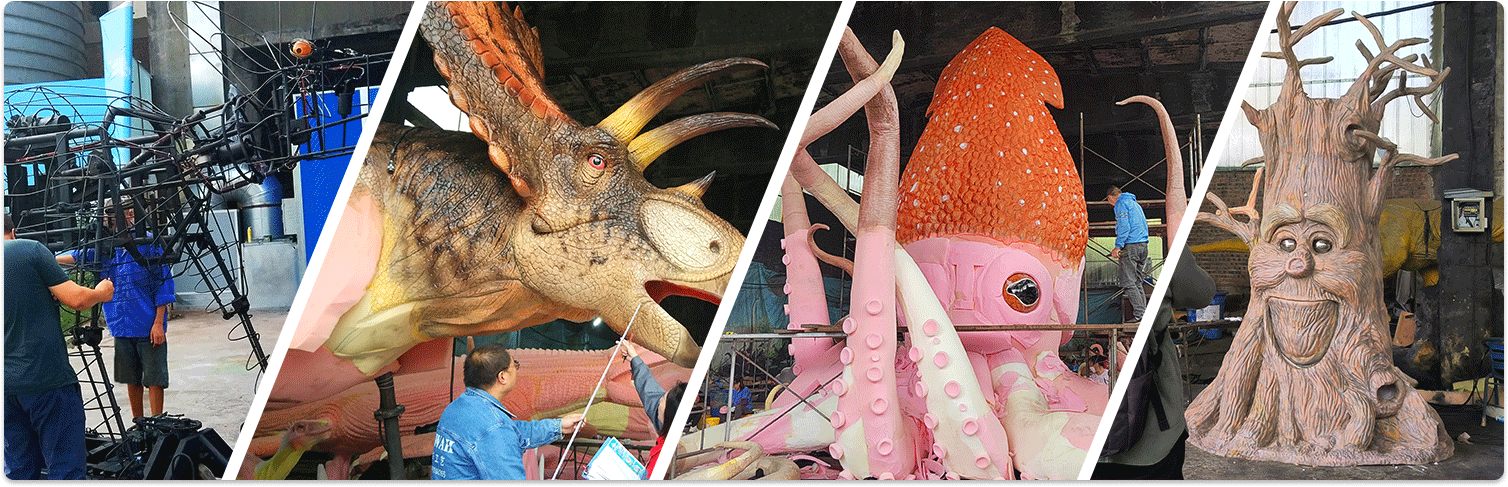

Kawah Dinosaur Factory offers three types of customizable simulated animals, each with unique features suited to different scenarios. Choose based on your needs and budget to find the best fit for your purpose.

· Sponge material (with movements)

It uses high-density sponge as the main material, which is soft to the touch. It is equipped with internal motors to achieve a variety of dynamic effects and enhance attraction. This type is more expensive requires regular maintenance, and is suitable for scenarios that require high interactivity.

· Sponge material (no movement)

It also uses high-density sponge as the main material, which is soft to the touch. It is supported by a steel frame inside, but it does not contain motors and cannot move. This type has the lowest cost and simple post-maintenance and is suitable for scenes with limited budget or no dynamic effects.

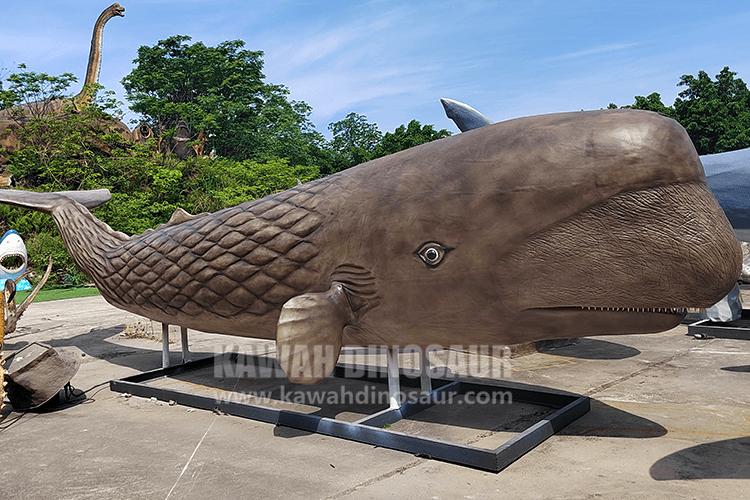

· Fiberglass material (no movement)

The main material is fiberglass, which is hard to the touch. It is supported by a steel frame inside and has no dynamic function. The appearance is more realistic and can be used in indoor and outdoor scenes. Post-maintenance is equally convenient and suitable for scenes with higher appearance requirements.

Why choose Kawah Dinosaur?

1. With 14 years of profound experience in manufacturing simulation models, Kawah Dinosaur Factory continuously optimizes production processes and techniques and has accumulated rich design and customization capabilities.

2. Our design and manufacturing team uses the customer's vision as a blueprint to ensure that each customized product fully meets the requirements in terms of visual effects and mechanical structure, and strives to restore every detail.

3. Kawah also supports customization based on customer pictures, which can flexibly meet the personalized needs of different scenarios and uses, bringing customers a customized high-standard experience.

1. Kawah Dinosaur has a self-built factory and directly serves customers with a factory direct sales model, eliminating middlemen, reducing customers' procurement costs from the source, and ensuring transparent and affordable quotations.

2. While achieving high-quality standards, we also improve cost performance by optimizing production efficiency and cost control, helping customers maximize project value within budget.

1. Kawah always puts product quality first and implements strict quality control during the production process. From the firmness of welding points, the stability of motor operation to the fineness of product appearance details, they all meet high standards.

2. Each product must pass a comprehensive aging test before leaving the factory to verify its durability and reliability in different environments. This series of rigorous tests ensures that our products are durable and stable during use and can meet various outdoor and high-frequency application scenarios.

1. Kawah provides customers with one-stop after-sales support, from the supply of free spare parts for products to on-site installation support, online video technical assistance and lifetime parts cost-price maintenance, ensuring customers worry-free use.

2. We have established a responsive service mechanism to provide flexible and efficient after-sales solutions based on the specific needs of each customer, and are committed to bringing lasting product value and secure service experience to customers.