Realistic Dinosaur Lanterns Christmas Decorations Animal Lanterns Festival Supplier CL-2613

Product Video

What is Zigong Lantern?

Zigong lanterns are traditional lantern crafts from Zigong, Sichuan, China, and part of China's intangible cultural heritage. Known for their unique craftsmanship and vibrant colors, these lanterns are made from bamboo, paper, silk, and cloth. They feature lifelike designs of characters, animals, flowers, and more, showcasing rich folk culture. The production involves material selection, design, cutting, pasting, painting, and assembly. Painting is crucial as it defines the lantern’s color and artistic value. Zigong lanterns can be customized in shape, size, and color, making them ideal for theme parks, festivals, commercial events, and more. Contact us to customize your lanterns.

Materials for Zigong Lanterns

1 Chassis Material: The chassis supports the entire lantern. Small lanterns use rectangular tubes, medium ones use 30-angle steel, and large lanterns may use U-shaped channel steel.

2 Frame Material: The frame shapes the lantern. Typically, No. 8 iron wire is used, or 6mm steel bars. For larger frames, 30-angle steel or round steel is added for reinforcement.

3 Light Source: Light sources vary by design, including LED bulbs, strips, strings, and spotlights, each creating different effects.

4 Surface Material: Surface materials depend on the design, including traditional paper, satin cloth, or recycled items like plastic bottles. Satin materials provide good light transmission and a silk-like gloss.

Zigong Lanterns Parameters

| Materials: | Steel, Silk Cloth, Bulbs, LED Strips. |

| Power: | 110/220V AC 50/60Hz (or customized). |

| Type/Size/Color: | Customizable. |

| After-sale Services: | 6 months after installation. |

| Sounds: | Matching or custom sounds. |

| Temperature Range: | -20°C to 40°C. |

| Usage: | Theme parks, festivals, commercial events, city squares, landscape decorations, etc. |

Why choose Kawah Dinosaur?

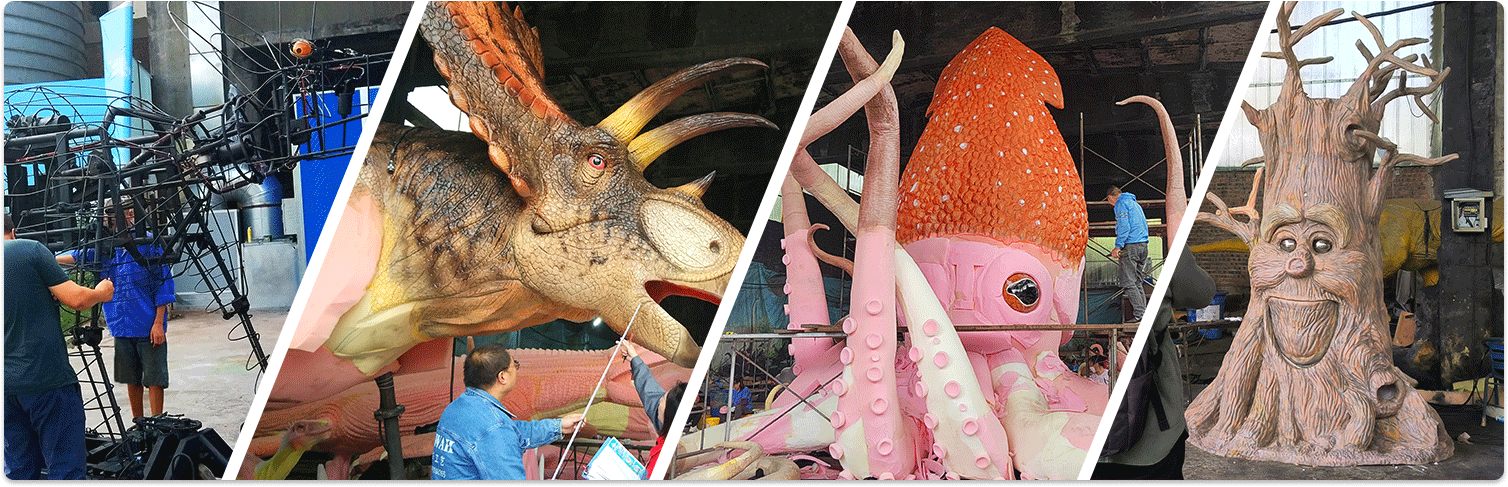

1. With 14 years of profound experience in manufacturing simulation models, Kawah Dinosaur Factory continuously optimizes production processes and techniques and has accumulated rich design and customization capabilities.

2. Our design and manufacturing team uses the customer's vision as a blueprint to ensure that each customized product fully meets the requirements in terms of visual effects and mechanical structure, and strives to restore every detail.

3. Kawah also supports customization based on customer pictures, which can flexibly meet the personalized needs of different scenarios and uses, bringing customers a customized high-standard experience.

1. Kawah Dinosaur has a self-built factory and directly serves customers with a factory direct sales model, eliminating middlemen, reducing customers' procurement costs from the source, and ensuring transparent and affordable quotations.

2. While achieving high-quality standards, we also improve cost performance by optimizing production efficiency and cost control, helping customers maximize project value within budget.

1. Kawah always puts product quality first and implements strict quality control during the production process. From the firmness of welding points, the stability of motor operation to the fineness of product appearance details, they all meet high standards.

2. Each product must pass a comprehensive aging test before leaving the factory to verify its durability and reliability in different environments. This series of rigorous tests ensures that our products are durable and stable during use and can meet various outdoor and high-frequency application scenarios.

1. Kawah provides customers with one-stop after-sales support, from the supply of free spare parts for products to on-site installation support, online video technical assistance and lifetime parts cost-price maintenance, ensuring customers worry-free use.

2. We have established a responsive service mechanism to provide flexible and efficient after-sales solutions based on the specific needs of each customer, and are committed to bringing lasting product value and secure service experience to customers.