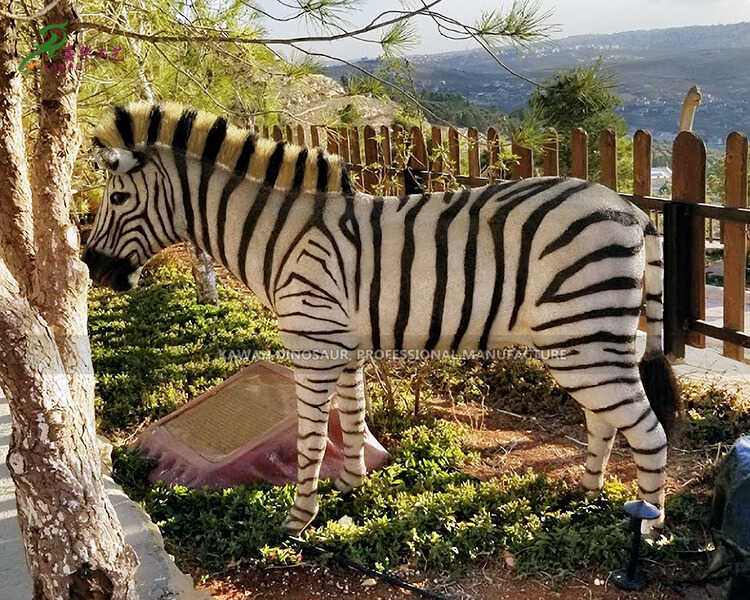

Zoo Park Simulated Zebra Statue Life Size Animal Animatronic Customized AA-1226

Product Video

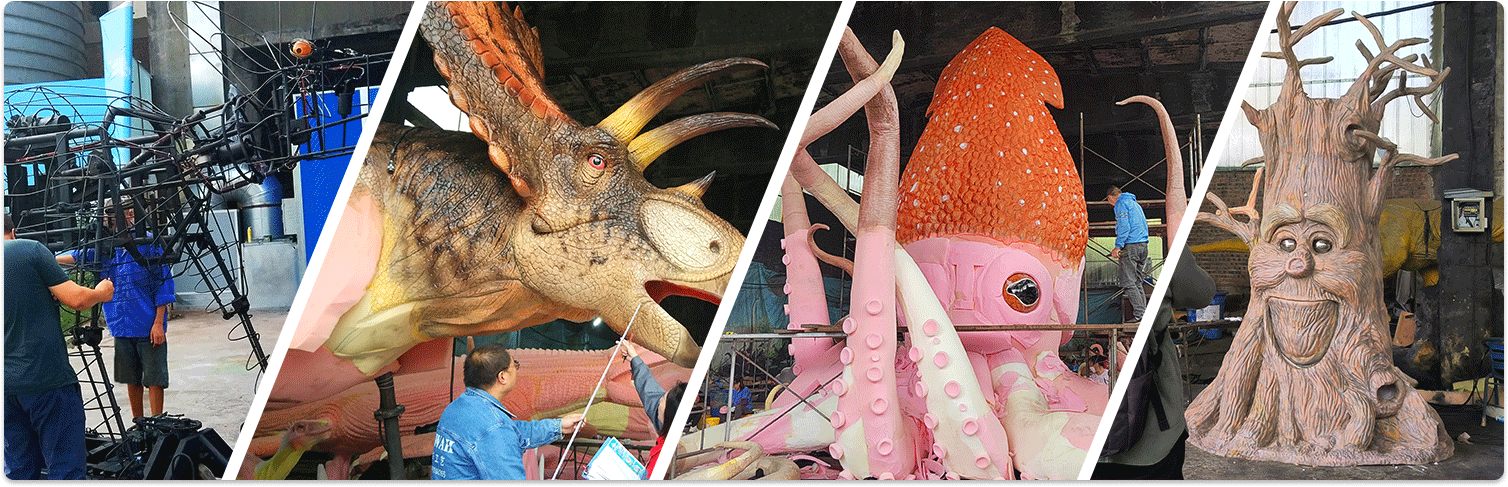

What are Animatronic Animals?

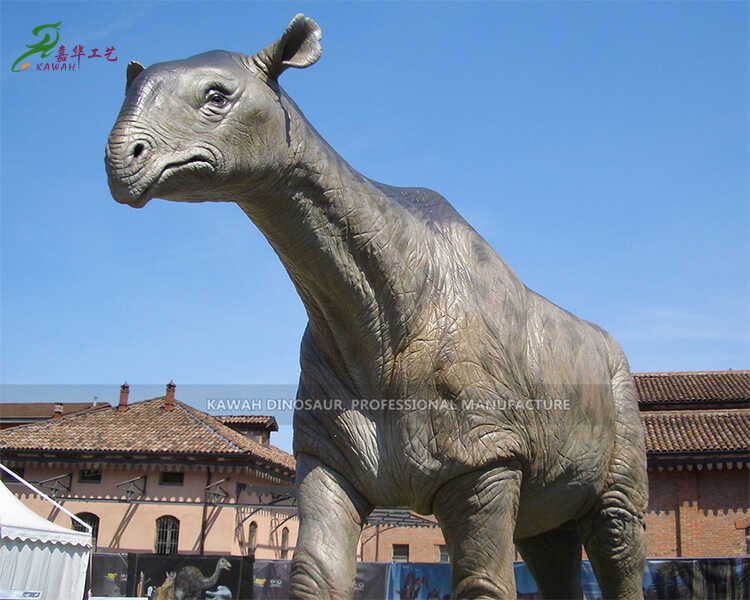

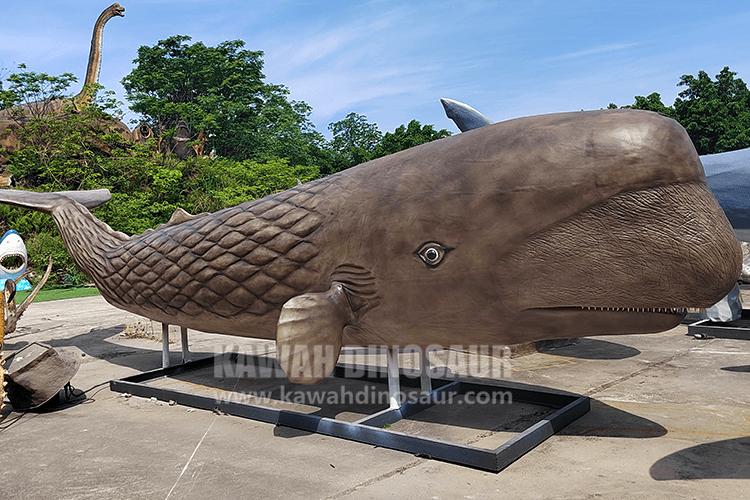

Simulated animatronic animals are lifelike models crafted from steel frames, motors, and high-density sponges, designed to replicate real animals in size and appearance. Kawah offers a wide range of animatronic animals, including prehistoric creatures, land animals, marine animals, and insects. Each model is handcrafted, customizable in size and posture, and easy to transport and install. These realistic creations feature movements like head rotation, mouth opening and closing, eye blinking, wing flapping, and sound effects such as lion roars or insect calls. Animatronic animals are widely used in museums, theme parks, restaurants, commercial events, amusement parks, shopping centers, and festival exhibitions. They not only attract visitors but also provide an engaging way to learn about the fascinating world of animals.

Animatronic Animals Features

· Realistic Skin Texture

Hand-Crafted with high-density foam and silicone rubber, our animatronic animals feature lifelike appearances and textures, offering an authentic look and feel.

· Interactive Entertainment & Learning

Designed to provide immersive experiences, our realistic animal products engage visitors with dynamic, themed entertainment and educational value.

· Reusable Design

Easily disassembled and reassembled for repeated use. Kawah factory’s installation team is available for on-site assistance.

· Durability in All Climates

Built to withstand extreme temperatures, our models feature waterproof and anti-corrosion properties for long-lasting performance.

· Customized Solutions

Tailored to your preferences, we create bespoke designs based on your requirements or drawings.

· Reliable Control System

With strict quality checks and over 30 hours of continuous testing before shipment, our systems ensure consistent and reliable performance.

Why choose Kawah Dinosaur?

1. With 14 years of profound experience in manufacturing simulation models, Kawah Dinosaur Factory continuously optimizes production processes and techniques and has accumulated rich design and customization capabilities.

2. Our design and manufacturing team uses the customer's vision as a blueprint to ensure that each customized product fully meets the requirements in terms of visual effects and mechanical structure, and strives to restore every detail.

3. Kawah also supports customization based on customer pictures, which can flexibly meet the personalized needs of different scenarios and uses, bringing customers a customized high-standard experience.

1. Kawah Dinosaur has a self-built factory and directly serves customers with a factory direct sales model, eliminating middlemen, reducing customers' procurement costs from the source, and ensuring transparent and affordable quotations.

2. While achieving high-quality standards, we also improve cost performance by optimizing production efficiency and cost control, helping customers maximize project value within budget.

1. Kawah always puts product quality first and implements strict quality control during the production process. From the firmness of welding points, the stability of motor operation to the fineness of product appearance details, they all meet high standards.

2. Each product must pass a comprehensive aging test before leaving the factory to verify its durability and reliability in different environments. This series of rigorous tests ensures that our products are durable and stable during use and can meet various outdoor and high-frequency application scenarios.

1. Kawah provides customers with one-stop after-sales support, from the supply of free spare parts for products to on-site installation support, online video technical assistance and lifetime parts cost-price maintenance, ensuring customers worry-free use.

2. We have established a responsive service mechanism to provide flexible and efficient after-sales solutions based on the specific needs of each customer, and are committed to bringing lasting product value and secure service experience to customers.

Kawah Dinosaur Certifications

At Kawah Dinosaur, we prioritize product quality as the foundation of our enterprise. We meticulously select materials, control every production step, and conduct 19 strict testing procedures. Each product undergoes a 24-hour aging test after the frame and final assembly are completed. To ensure customer satisfaction, we provide videos and photos at three key stages: frame construction, artistic shaping, and completion. Products are shipped only after receiving customer confirmation at least three times. Our raw materials and products meet industry standards and are certified by CE and ISO. Additionally, we have obtained numerous patent certificates, showcasing our commitment to innovation and quality.